Power that moves you.

Rigid carbon composite panels for things that move.

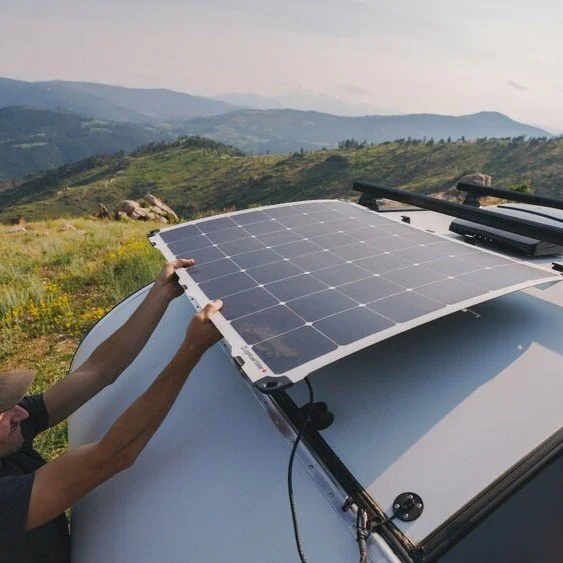

We provide ultralight, rigid solar panels with incredibly convenient design.

Our rugged carbon fiber solar panels are designed to seamlessly integrate with trailers, sailboats, vehicles, and more. If it moves, we can power it - with panels that are ultralight, efficient, and uncompromising in their strength.

Our panels

-

seaLeaf

Lightweight, rigid, rail-mounted solar panels for boats.

-

dropLeaf

Deployable, rigid, lightweight solar for small trailers.

-

uLeaf

Rigid, lightweight and rugged solar for portable applications.

-

gLeaf

Rigid and lightweight fixed mount solar to power any mobile project.

Just 5 pounds and 9 millimeters thin.

LightLeaf Solar panels are engineered to enhance your outdoor experience. Our leading-edge technology combines rigidity and functionality, with an unbending foundation of carbon fiber strengthening every panel without any sacrifice.

From our customers

Learn more about our solar panels.

-

Aerospace-style carbon/foam sandwich construction makes our panels stiff and strong. This allows clean and versatile mounting, and protects the monocrystalline cells from flexing and cracking.

-

Our panels are 1/4 the weight of standard glass panels and just 8mm thin. They are a breeze to haul around, weighing a mere 5 pounds.

-

Thick, tough, scratch-resistant polycarbonate and carbon/foam construction stands up to abuse. LightLeaf Solar panels are built to withstand anything from harsh winters to rough seas.

-

Our solar panels are designed and manufactured in Canada, using quality materials sourced from throughout North America.

LET’S GET SOCIAL!

Frequently asked questions.

-

The gLeaf Is designed for general purpose, permanent mounting. These lightweight, rigid panels have a strong durable perimeter flange that can be drilled, clamped or otherwise attached to almost any surface. The dropLeaf is designed to work with our proprietary quick release hardware to allow mounting on a teardrop trailer, yet still be removable for remote charging.

-

The possibilities are endless. A single 100W solar panel can produce approximately 600 W-hrs of electricity during a single, central North-American, sunny day. It can produce the power required for a small trailer, including lighting, device charging, a compression-style refrigerator, and miscellaneous loads. However, it would not be enough to operate air-conditioning, or heaters.

In addition, it could charge a 1 kWh portable power station in approximately 1.5 days from fully discharged.

-

Yes - these can be connected either in series or parallel. Either method has their pros and cons dependent on the mounting location and the application. It is not easy to make a blanket statement to indicate which is the best. Note that if these are mounted in parallel, a blocking diode is required for each panel. The controller should be sized to handle the panels you have connected.

-

Our panels do not come with controllers, but a solar controller is required to protect and most efficiently charge your battery system. Note that some battery power stations contain a built-in controller. However, the solar panel should not be connected directly to a 12V battery.

-

Normally, panels are provided as an OEM option from the particular trailer manufacturer you choose. Contact them first. Alternatively, we supply a generic model - the Generic dropLeaf - with a generalized curvature that fits many trailers.

-

All solar panels’ performance is significantly reduced in partial shading conditions. If a single or small group of cells is shaded, that can block the output of the entire solar panel. LightLeaf solar panels incorporate two features to minimize this. First, Maxeon high-performance cells are used in all of our panels. They are inherently less sensitive to partial shading. Second, Schottky bypass diodes are incorporated into our junction box to effectively bypass shaded cells to maximize output.

-

No, we do not manufacture without the curve. However, we do have some variance with the amount of curve. Typically, they are installed with the curve on flat surfaces.

-

There is no power advantage or disadvantage with the amount of curve we use.

-

We don't build them to be walked on. Some customers have done this but we don't encourage it. These panels can comfortably support 80lbs. Depending on the canoe you should be comfortable supporting this weight. However, when ratcheted down and doing highway; I don't know

-

Very resilient. Our polycarbonate front sheet is very durable. Our trailer partner, Bean Trailer, use our panels as a window rock guard. Under this layer of polycarbonate we use Sabic HP12W. A proven UV treated sheet which will prevent hazing.

-

These panels are the best on the market at 24.9% efficient. The most efficient cells available are SunPower Maxeon monocrystalline cells and that is what we use. Cheaper panels are about ~21% efficient.

-

This is a lot to do with how they are wired. An array of cells are typically wired in series. I.e. If one cell is in the shade all cells perform as well as that shaded cell. Our junction boxes are manufactured with 2 Schottky bypass diodes. These diodes separate these cells into 3 different arrays. This ensures greater charge efficiency and circuit protection.

Also, our panels are super light. We manufacture our panels with a nice kickstand. So if you are in the shade; you pop the panel off and set it up in the sun.

-

The curve really helps with preventing dust accumulation. It also allows for the panels to get a great clean and rinse in rain.

-

Basic calculations: If we were to customize a panel that would be 108" x 48". that would be 36 sq ft. and give us about 575W. A custom project with that much wattage would cost about $7,000.

-

Many of our panels are being used as a rock guard. This is a testament to the strength but we cannot give a specific value.

-

A conclusive test would be to check Isc and Voc, as follows:

1. Disconnect the panel from the socket on the trailer or bulkhead

2. In bright sunshine, measure short-circuit current (Isc), and open circuit voltage (Voc) of the isolated panel - with a multi-meter.

3. Values should match the specifications given on the back of the panel. Note that the positive pin is shrouded on the solar connector.